THERMAL PRINTER CUTTER TYPES - DO YOU KNOW THE DIFFERENCE? THE FIRST (WRONG) CUT IS THE DEEPEST

Let’s face it, ALL printers jam on occasion and can’t properly feed the ticket out correctly.

There are two basic reasons for this and this article addresses both to ensure that you are making the proper decision when selecting a printer for your application.

Here are the issues:

Did you choose the right printer cutting type for your application?

How does your machine feed the printed ticket to the patron?

The above questions are very interrelated as described below.

Let’s Go

So you make your machine and it contains a printer of some sort. Testing at your facility goes great. Your engineering folks are happy with the design and it goes into the field. During this time, you are hearing customers reporting paper jams inside the printer. What’s going on? So you test and retest at your facility and all works well but the end customer is still reporting paper jams.

What is going on here?

It may be that you have chosen a printer with the wrong cutting and feed type for your application.

OK, let’s talk about what printers/cutter types are available to you.

There are three basic printer cutting methods: Pull to cut, Printer Cutter type and Presenter Cutter type printers

Pull to Cut

The first type of printer is a pull to cut or tear-off design and is not really a cutter at all. These rely on the patron to pull on the ticket to automatically tear it off using a serrated type blade. Think something like a steak knife that you pull the paper over and essentially rip the paper in a uniform manner. In terms of jams, this model will have the highest rate of patron jams since you are letting the patron determine how well or poorly the ticket is torn.

For example: On occasion a simple pulling of the paper at a sideways angle will cause a jam. The patron may get the ticket out OK, but the next patron may very well experience a printer jam, since the paper is now crumbled inside the printer and is stuck on the knife blade due to the previous patron pulling the paper out and interrupting the way this printer normally functions. This is particularly true in applications where the patron is in a hurry to get his ticket and get out of there.

Hey, you just let the patron determine how well your printer works!

Many applications utilize this type of printer, since it is a lower cost printer. The printer does not have a motorized blade in it that precisely cuts the paper. Petrol stations are a prime example of this. Many pumps have the serrated blade printer and a quick pull straight on the paper, then at a sharp angle, may cause a jam for the next patron. Now, your machine is down until someone corrects the jam situation.

You didn’t find this problem during your internal tests, but now you have a big problem on your hands.

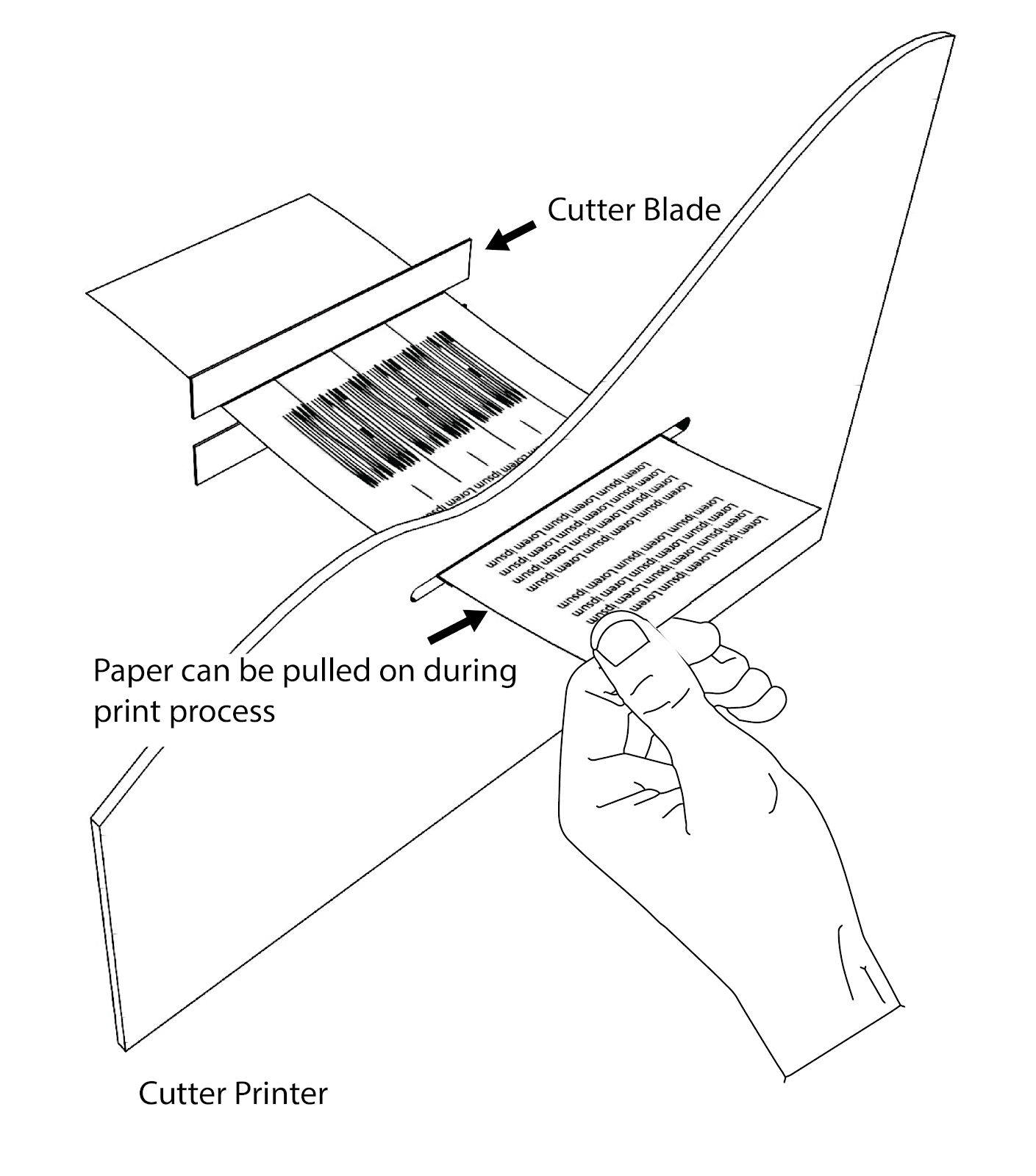

Printer Cutter Type

The next type of printer is a “cutter” type printer. These are a little more expensive due to the requirement of having a motorized blade to precisely cut the paper. Think a pair of scissors inside the printer.

The printer prints the ticket and when completed, the printer cuts the paper in a nice fashion with its motorized blade. Sounds great.

Now let’s look at a potential jam scenario:

As the paper is being printed and shown to the patron, the patron has the ability to pull on the paper before it is done being printed and cut. If the paper rips off inside the printer before the cut, then you may have a jam. Worse yet, the printer doesn’t know this and then cuts the rest of the paper that may be stuck inside the printer. Now, you have a small piece of paper stuck inside the unit. Jam, jam, jam.

In case you weren’t paying attention, once again, you just let the patron determine how well your printer works!

Presentor Cutter Type Printer

The ultimate in printer technology (and being the most jam resistant due to patron interaction) is the “Presenter” type cutting printer. This printer fully prints and cuts the paper before it is presented to the patron. This eliminates the major problem of jams related to patron interaction.

Here’s how this type of printer works:

As the printer is printing the ticket, the ticket slightly rolls either over or under the printer inside the machine. During this time, the printer is holding the paper back so that it is not presented to the patron. Once the entire ticket is printed, the printer will cut the ticket and the presenter mechanics will feed a portion of the ticket to the patron. The patron grabs the ticket and pulls out the ticket cleanly. Using this method, the ticket is printed and cut before it is ever available to the patron. The printer always has full control of the paper and thus patron interaction with the printer is zero. In other words, patron related jams are virtually eliminated.

Which printer cutter type to use is one of the most overlooked aspects of printer selection but can cause the most grief in the field. Pick wisely.